System Approach

Consider a factory that produces products such as pencils. To produce a pencil, there must be a system of work designed and organized to handle raw material and process them over several steps to produce the final product, pencils. This system as a whole is very complex and difficult, if not impossible to manage in its entirety. So, the system must be divided into smaller work processes. Each process can be defined clearly as series of task that handle an "input" to produce an "output".

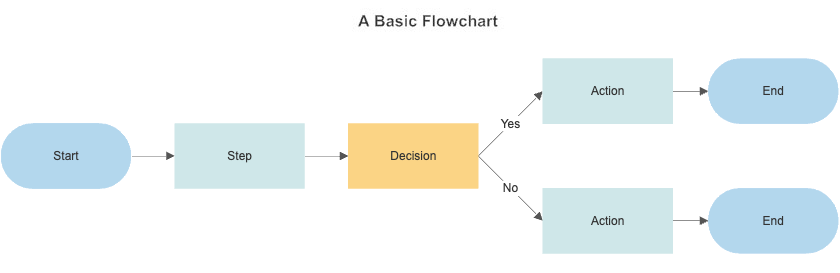

Similarly, in the laboratory, there is a complex system of work that can be divided into several processes. Each process starts with an "input" followed by a series of "tasks" to produce an "output". For example, sample collection is a process that starts with an "oder" request from a clinic. This order is followed by a series of tasks such as patient identification, preparation, venipuncture and collection of blood in designated tubes. The output of "blood collection" is a sample of blood in a tube.

All laboratory work is divided in such a way to clearly define several work processes. These processes are then managed in an effective way by monitoring key performance indicators. This ensures the effectiveness of the process and enable continuous improvement of performance.